Revolutionizing Hydraulic Cylinder Systems The Ultimate Guide to 2025 Industry Innovations

The Hydraulic Cylinder System industry is on the brink of transformative change, with innovations set to redefine operational efficiency and functionality by 2025. According to a recent market analysis report by ResearchAndMarkets, the global hydraulic cylinder market is expected to grow from $16.1 billion in 2020 to $26.7 billion by 2025, driven by increasing demand for advanced automation in manufacturing and construction sectors. This evolution is characterized by the integration of smart technologies, including IoT-enabled sensors and predictive maintenance solutions, aimed at enhancing the performance and lifespan of hydraulic systems.

As industries seek to minimize downtime and optimize performance, the focus on revolutionary designs and efficiency standards in Hydraulic Cylinder Systems has never been greater. This ultimate guide aims to explore the cutting-edge trends and innovations that are shaping the future of hydraulic cylinders, providing insights into how these advancements are paving the way for enhanced productivity and sustainability in various applications.

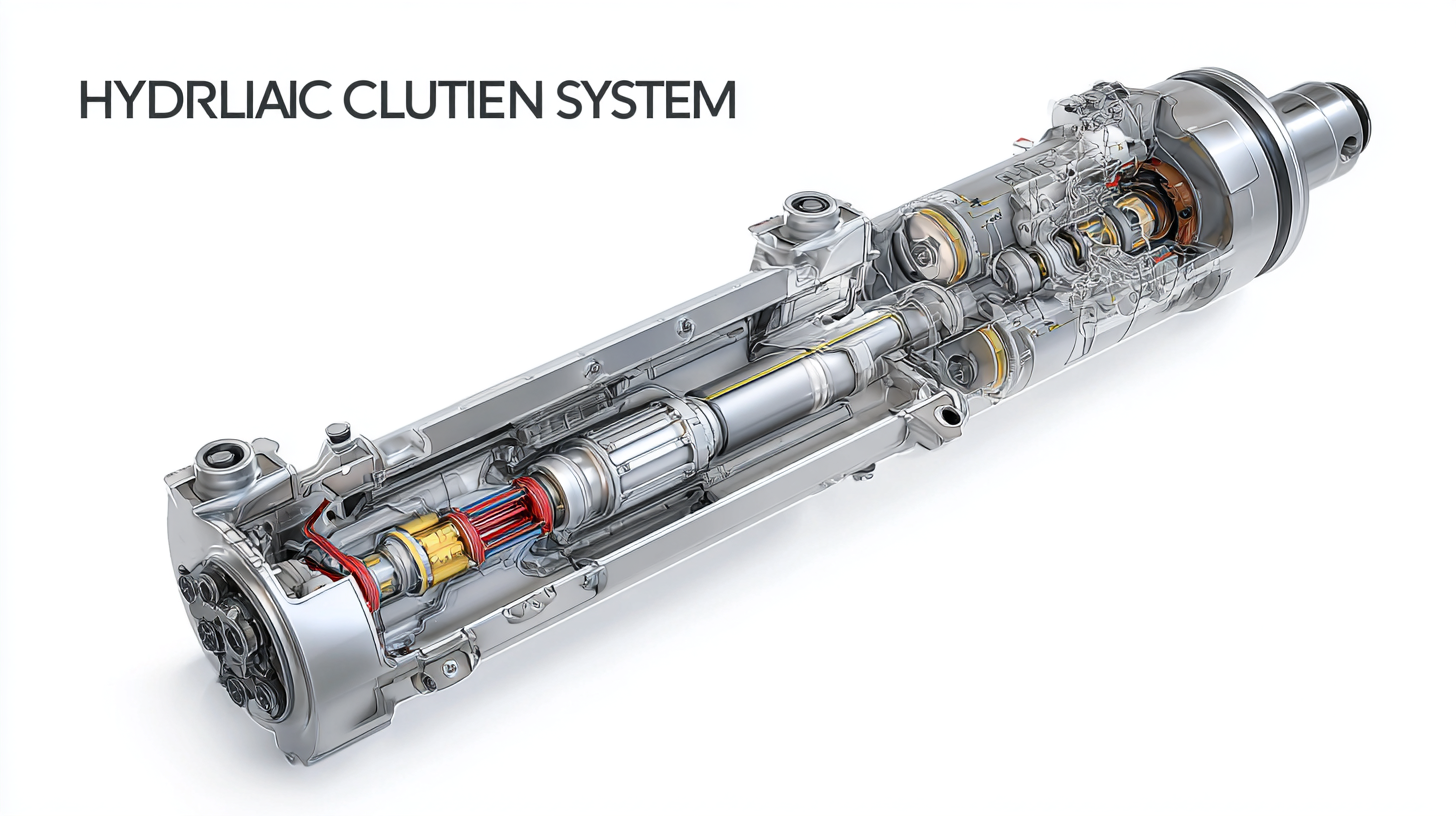

Innovative Material Technologies Transforming Hydraulic Cylinder Design

In the dynamic landscape of hydraulic cylinder systems, innovative material technologies are at the forefront of transforming design and functionality. With advancements in composites, lightweight metals, and smart materials, manufacturers are able to enhance performance while reducing weight and improving durability.

These materials not only contribute to the efficiency of hydraulic operations but also offer greater resistance to wear and corrosion, ultimately extending the life of the cylinders.

Tip: When selecting materials for hydraulic cylinder design, consider the specific application and environmental conditions. For example, using corrosion-resistant materials in marine environments can drastically improve longevity and performance.

Moreover, the integration of smart materials, such as shape memory alloys, enables these systems to adapt to varying operational demands. By responding to changes in temperature or pressure, these advanced materials can optimize the hydraulic function dynamically, leading to improved efficiency and reduced energy consumption.

Tip: Always stay updated on the latest innovations in material technology to ensure that your hydraulic systems are equipped with the best components for their specific applications. Regularly attending industry trade shows can help you discover cutting-edge solutions and best practices.

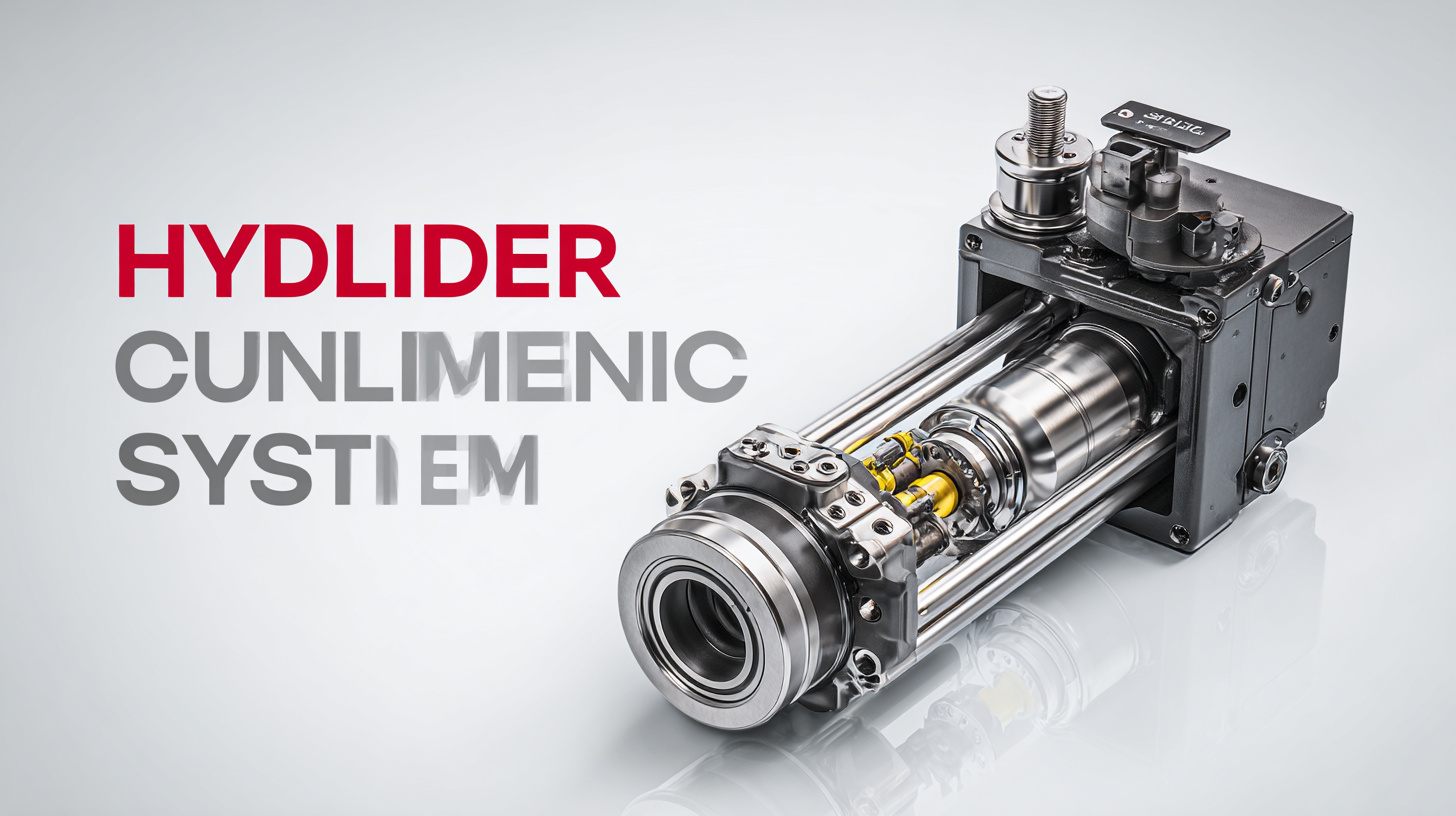

Smart Automation: The Future of Hydraulic Cylinder Control Systems

In the rapidly evolving landscape of hydraulic cylinder control systems, smart automation is set to redefine industry standards by 2025. The integration of advanced sensors and IoT technology enables real-time data processing and remote monitoring, allowing for unparalleled precision in control and operation. This shift not only enhances the efficiency of hydraulic systems but also minimizes downtime, as operators can promptly identify and address issues before they escalate.

Furthermore, the adoption of machine learning algorithms and AI-driven analytics leads to predictive maintenance models that optimize performance. By analyzing historical data and identifying patterns, these systems can anticipate failures, reduce costs, and extend the lifespan of hydraulic cylinders. As companies invest in smart automation, they are not only streamlining operations but also increasing safety and reliability in demanding industrial environments.

The future of hydraulic systems is bright, and with smart technology at the helm, the industry is poised for a revolutionary transformation.

Sustainability in Manufacturing: Eco-Friendly Practices in Hydraulic Cylinder Production

Sustainability in hydraulic cylinder manufacturing is gaining traction as industries prioritize eco-friendly practices. The hydraulic seals market, projected to reach significant growth, highlights a shift towards materials that minimize environmental impact. Reports indicate that elastomers, used in hydraulic piston and rod seals, are becoming increasingly favored for their durability and lower ecological footprint. This transition not only enhances the performance of hydraulic systems but also aligns with global sustainability goals.

Sustainability in hydraulic cylinder manufacturing is gaining traction as industries prioritize eco-friendly practices. The hydraulic seals market, projected to reach significant growth, highlights a shift towards materials that minimize environmental impact. Reports indicate that elastomers, used in hydraulic piston and rod seals, are becoming increasingly favored for their durability and lower ecological footprint. This transition not only enhances the performance of hydraulic systems but also aligns with global sustainability goals.

Moreover, innovative manufacturing techniques like 3D printing are emerging as game-changers in reducing waste and energy consumption within the hydraulic sector. By optimizing production processes, companies can effectively decrease their carbon footprint while maintaining high-quality standards. Research reveals that 3D printing can significantly lower material usage and facilitate more sustainable design elements, making it an essential tool for manufacturers looking to revolutionize their operations and adhere to greener practices in the coming years. As industries continue to integrate these advancements, the potential for a more sustainable future in hydraulic cylinder production becomes increasingly viable.

Global Market Trends: Growing Demand for High-Quality Hydraulic Solutions

The global market for hydraulic solutions is experiencing significant growth, driven by increasing demand for high-quality hydraulic systems across various industries. According to a recent analysis by Custom Market Insights, the global industrial hydraulic equipment market is expected to reach a staggering USD 52.6 billion by 2033, representing a compound annual growth rate (CAGR) of 5.7%. This escalating demand reflects the critical role hydraulics play in sectors including construction, manufacturing, and oil and gas.

Moreover, the hydraulic hose and fittings market is projected to witness a growth rate of 4%, fueled by advancements in technology and enhanced product offerings. As industries continue to prioritize efficiency and reliability in hydraulic solutions, the hydraulic pumps market is forecasted to grow significantly, with estimates suggesting it will rise from USD 10.9 billion in 2024 to USD 13.7 billion by 2030. This momentum signifies a robust trend towards high-quality hydraulic products, ensuring that industries can meet their operational demands while leveraging innovative hydraulic technologies.

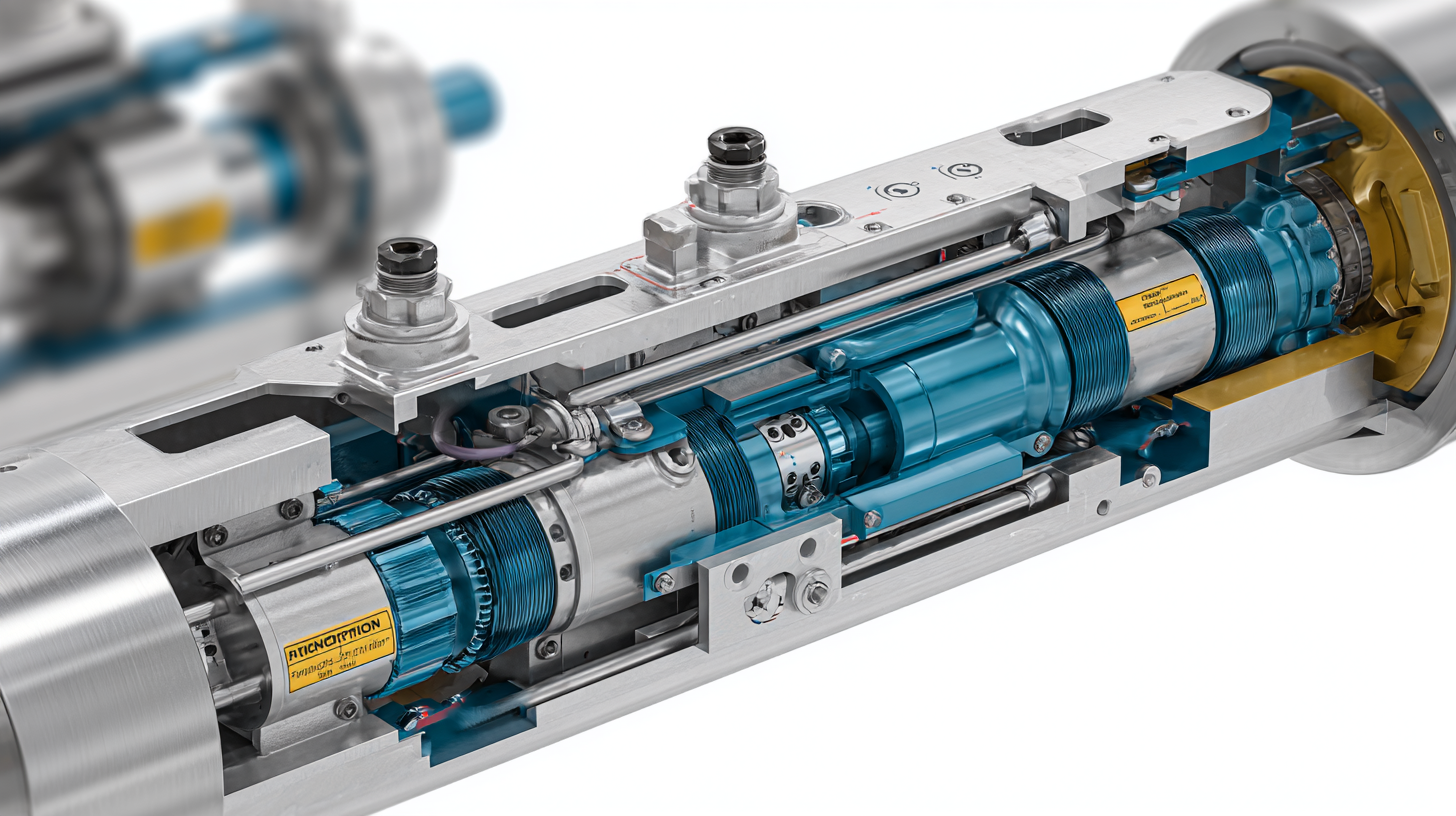

Boosting Performance: Latest Advances in Hydraulic Cylinder Efficiency and Durability

In recent years, the hydraulic cylinder industry has witnessed significant advancements aimed at enhancing efficiency and durability. According to a report by MarketsandMarkets, the global hydraulic cylinder market is projected to reach USD 20.7 billion by 2025, growing at a CAGR of 5.3% from 2020. This growth can be attributed to innovations such as advanced seal designs and high-strength materials that extend operational lifetimes and reduce maintenance costs. The deployment of smart sensors within hydraulic cylinders has also improved performance monitoring, enabling predictive maintenance strategies that minimize downtime.

Moreover, the introduction of eco-friendly hydraulic fluids contributes to higher efficiency levels while reducing environmental impact. A study published in the Journal of Fluid Power indicates that using biodegradable fluids can enhance system performance by up to 15% compared to traditional oils. Manufacturers are now focusing on designing cylinders that not only meet stringent durability standards but also operate more sustainably. These innovations are setting new benchmarks for hydraulic systems in various industries, including construction, manufacturing, and aerospace, thereby revolutionizing the way hydraulic cylinders operate and are perceived within the market.

Revolutionizing Hydraulic Cylinder Systems The Ultimate Guide to 2025 Industry Innovations

| Dimension | 2023 Value | 2025 Forecast | Comments |

|---|---|---|---|

| Cylinder Efficiency (%) | 82 | 90 | Expected advancements in material technology. |

| Average Operating Pressure (psi) | 2000 | 2200 | Higher pressures allow for better performance. |

| Average Lifecycle (Years) | 10 | 12 | Durability improvements from advanced coatings. |

| Failure Rate (% per year) | 3 | 1.5 | Enhanced reliability through design innovations. |

| Weight (lbs) | 150 | 140 | Use of lighter composite materials. |