China Manufacturing Thrives with Best Hydraulic Cylinder Parts Amidst US China Tariff Challenges

In the face of escalating trade tensions and reciprocal tariffs between the United States and China, the resilience of Chinese manufacturing has become a topic of significant interest. Among the sectors thriving amidst these challenges, the production of Hydraulic Cylinder Parts stands out for its robust growth and innovation. As global industries seek to mitigate the impacts of tariffs, Chinese manufacturers have leveraged their expertise and supply chain efficiency to deliver high-quality hydraulic components that meet international standards. This blog will explore how the strategic focus on hydraulic cylinder parts not only strengthens China’s manufacturing sector but also plays a crucial role in maintaining competitive advantages in a global market increasingly shaped by protectionist policies. Through a closer examination of this industry's dynamics, we will uncover the factors driving growth and the implications for both Chinese and global markets amid ongoing geopolitical shifts.

The Resilience of China’s Manufacturing Sector Amid Trade Tensions

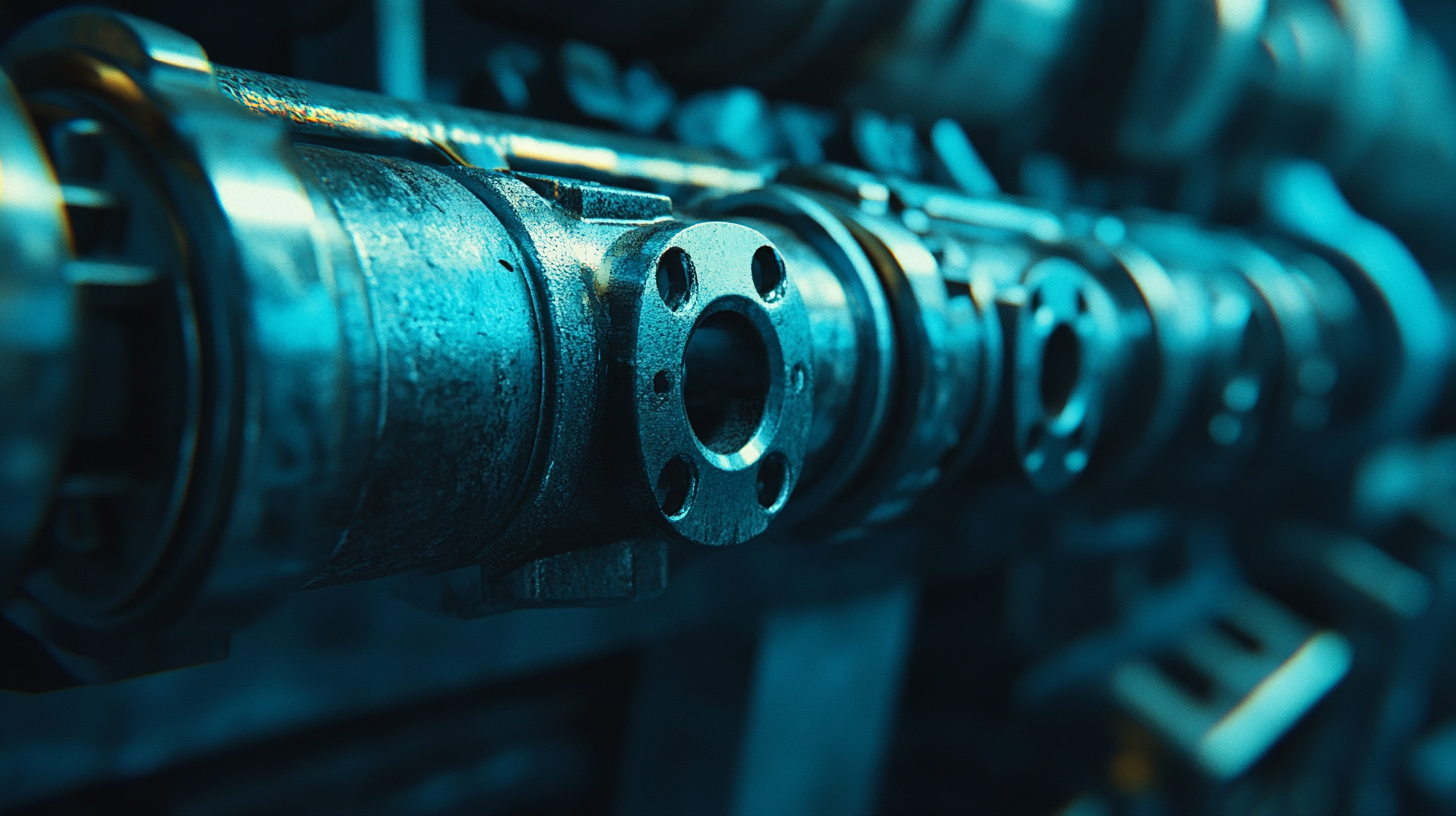

Amid ongoing trade tensions and tariff challenges between the United States and China, the resilience of China’s manufacturing sector has become increasingly evident. Despite facing significant barriers, Chinese manufacturers are adapting and thriving by innovating and improving their production processes. One area where this is particularly notable is in the production of hydraulic cylinder parts, which play a crucial role in various industrial applications. The ability of these manufacturers to deliver high-quality components at competitive prices showcases their commitment to excellence and their understanding of global market demands.

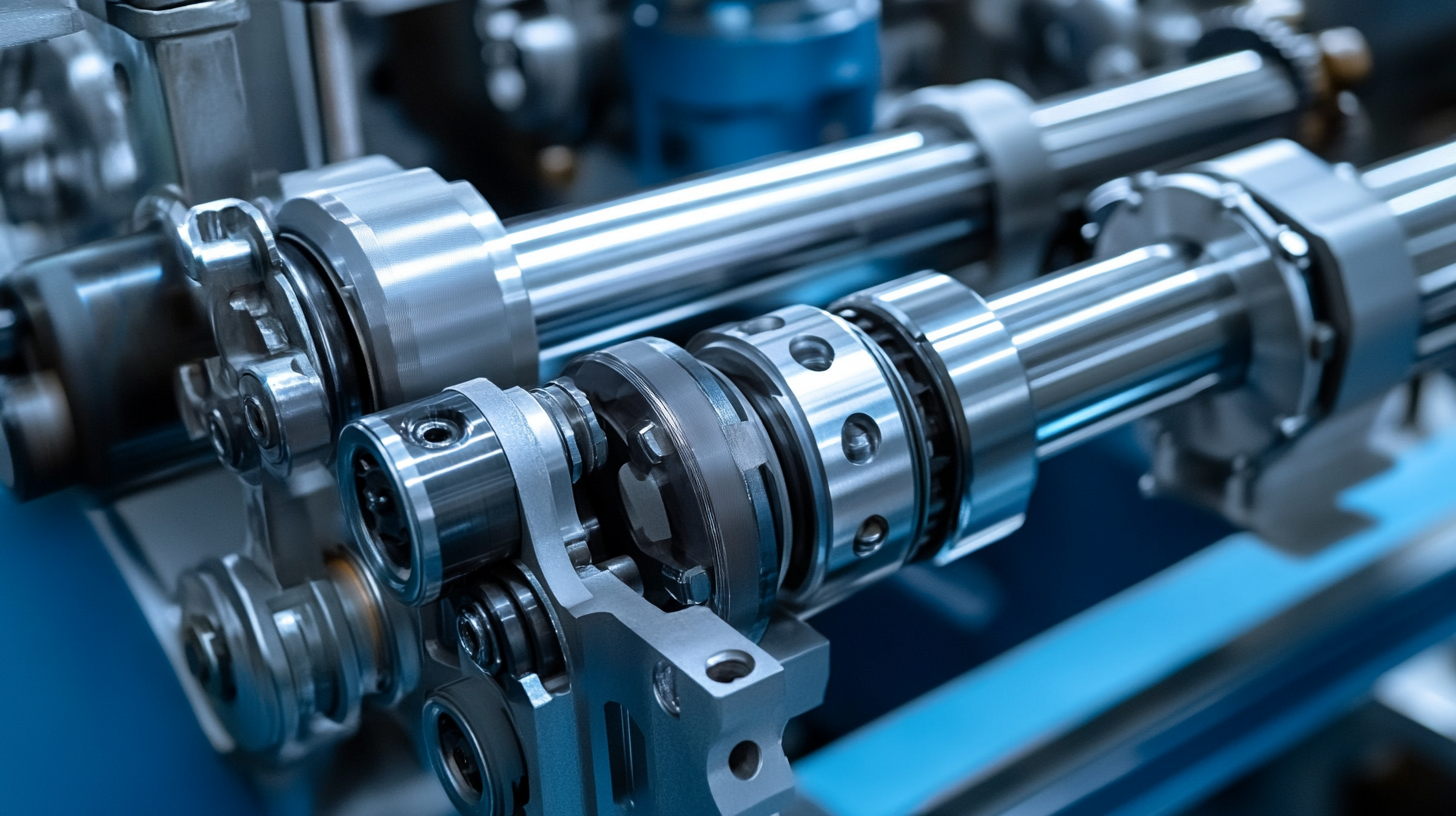

Moreover, the diversification of supply chains and the emphasis on advanced manufacturing technologies have fortified China's position in the global market. Chinese manufacturers are not only focusing on cost efficiency but also investing in research and development to enhance the performance and durability of their products. This dual approach not only mitigates the adverse effects of tariffs but also positions China as a leader in manufacturing specialized parts. As companies in other regions grapple with the challenges posed by tariffs, China’s manufacturing sector continues to adapt and find new growth avenues, reaffirming its vital role in the world economy.

China's Manufacturing Resilience Amid Trade Tensions

This chart illustrates the growth in production of hydraulic cylinder parts in China from 2020 to 2023, highlighting the manufacturing sector's resilience amid US-China trade tensions.

Key Factors Driving Growth in Hydraulic Cylinder Parts Manufacturing

Amidst the ongoing tariff challenges between the US and China, the manufacturing sector in China is experiencing remarkable growth, particularly in hydraulic cylinder parts. This surge can be attributed to several key factors, including technological advancements, a robust supply chain, and a skilled labor force. Chinese manufacturers are investing heavily in innovative technologies, enabling them to produce high-quality hydraulic cylinder parts that meet international standards. As demand for these components rises globally, companies are optimizing production processes to enhance efficiency and reduce costs.

Tips for success in this competitive landscape include focusing on quality control and embracing automation in manufacturing. By implementing strict quality assurance protocols, manufacturers can ensure that their products consistently meet buyer expectations and regulatory requirements. Moreover, adopting automation technologies not only speeds up production but also minimizes human error, ultimately leading to better product reliability.

Another vital aspect is building strong partnerships with suppliers and other stakeholders in the supply chain. Effective collaboration can lead to improved logistics and inventory management, allowing manufacturers to respond quickly to market demands. Investing in these key areas can significantly bolster a company's position in the hydraulic cylinder parts market, affirming their competitiveness on a global scale.

Hydraulic Cylinder Parts Market Distribution in China

How Tariff Challenges are Shaping Innovation in Chinese Industry

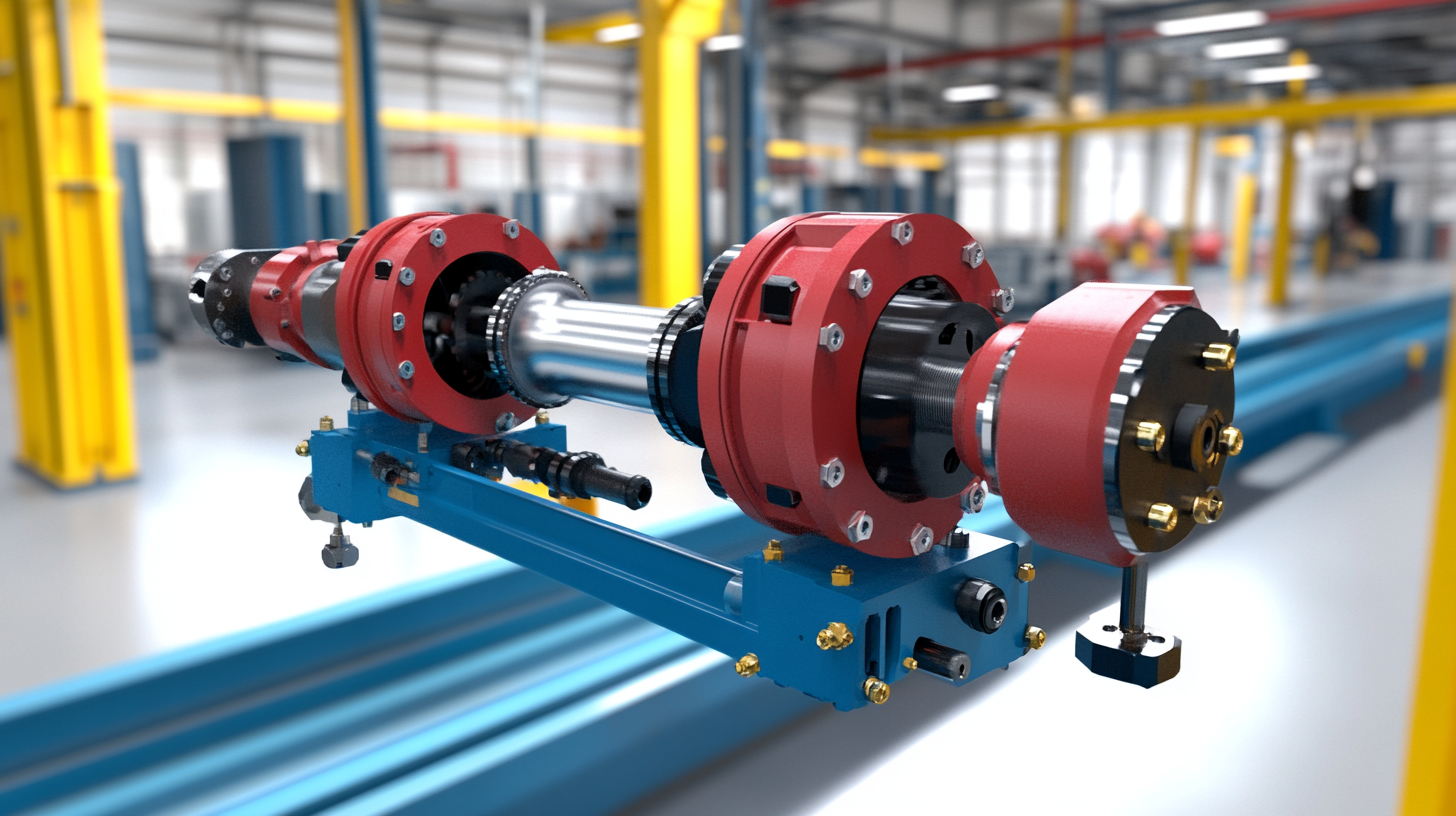

The ongoing U.S.-China trade tensions have ignited a transformative wave in the Chinese manufacturing landscape, with hydraulic cylinder parts emerging as a standout segment in innovation. Amidst tariff challenges, Chinese manufacturers are not only adapting but thriving. A report indicates that China's advanced industries are bolstered by a surge in domestic R&D investment, which has tripled over the past decade, fueling the development of high-quality components that meet international standards. This level of innovation is crucial for industries heavily reliant on precision and efficiency, proving that adversity can catalyze growth.

Furthermore, the introduction of tariffs on critical components such as steel and semiconductors is reshaping supply chains. Chinese companies are utilizing robust industrial chains to mitigate the effects of these tariffs. According to recent analyses, regions like Ningbo are successfully navigating the trade landscape by enhancing their supply chain resilience and maintaining competitive pricing. As these companies innovate and diversify production strategies, they not only address immediate challenges but also position themselves as leaders in the global market, ready to seize opportunities presented by shifts in the trade environment.

The Role of Quality and Technology in China's Manufacturing Success

China's manufacturing sector continues to shine, particularly in the high-quality hydraulic cylinder parts market, which stands resilient even amidst the challenging landscape of US-China tariffs. Key to this success is the emphasis on quality and advanced technology. A report from the Ministry of Industry and Information Technology highlights that over 80% of China's manufacturing companies have adopted digital technologies, significantly enhancing production efficiency and product quality. This modernization effort not only minimizes costs but also positions Chinese manufacturers to compete effectively on the global stage.

Recent developments, such as the successful test flight of the AG600 "Kunlong," showcase China's commitment to innovation in manufacturing. Analysts have noted that this aircraft will play a vital role in advancing China's capability in large-scale amphibious operations. Moreover, the country's strategic plan, "Made in China 2025," aims to elevate domestic manufacturing standards by increasing investment in high-tech industries. As noted by a Financial Times analysis, while this has strained relations with Western partners, it also reflects a shift towards self-reliance and technological prowess in sectors crucial for national development. This aligns with broader objectives set forth in the 2025 National Green and Low-Carbon Development Action Plan, emphasizing sustainable practices and technological integration across all manufacturing processes.

Global Market Opportunities for China’s Hydraulic Cylinder Industry

The landscape of China's hydraulic cylinder industry is evolving, creating significant global market opportunities despite ongoing tariff challenges from the United States. As manufacturers continue to innovate and enhance the quality of their hydraulic cylinder parts, they are not just meeting domestic demand but also capturing attention in international markets. The resilience and adaptability exhibited by these manufacturers enable them to navigate the complexities of global trade, allowing them to establish strong supply chains and build strategic partnerships worldwide.

Tip: To thrive in this competitive arena, companies should focus on investing in research and development, which can lead to the creation of superior hydraulic components that meet diverse global standards. Additionally, understanding local market requirements and regulations can foster better relationships with foreign buyers and facilitate smoother transactions.

As the demand for advanced hydraulic systems in agriculture, construction, and manufacturing sectors grows, China's manufacturers are well-positioned to seize these opportunities. By capitalizing on their expertise and leveraging international collaborations, they can expand their reach and influence in the global hydraulic cylinder market.

Tip: Building a robust online presence and utilizing digital marketing strategies can significantly enhance visibility and attract potential clients. Consider showcasing case studies and testimonials to build credibility and trust with international customers.