Exploring Diverse Alternatives for Hydraulic Cylinder Replacement Parts

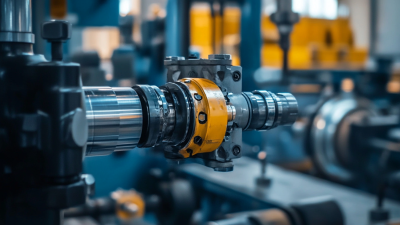

In the realm of industrial machinery and equipment, the performance and reliability of hydraulic systems are crucial. Central to these systems are hydraulic cylinders, which facilitate the movement and operation of various components. However, wear and tear over time can necessitate the need for hydraulic cylinder replacement parts. When seeking alternatives, it’s essential to explore a diverse range of options that can provide both functional reliability and cost-effectiveness.

This guide delves into the myriad alternatives available for hydraulic cylinder replacement parts, from OEM options to aftermarket solutions, helping you make informed decisions based on performance, durability, and budget considerations. By understanding the variety of choices, you can ensure the longevity and efficiency of your hydraulic systems while mitigating downtime and operational costs.

Identifying Common Issues with Hydraulic Cylinder Replacement Parts

When it comes to replacing hydraulic cylinder parts, several common issues can arise, impacting both performance and reliability. One frequent problem is the mismatch between new parts and the existing system, which can lead to inefficiencies and increased wear. Ensuring compatibility is crucial; always verify specifications and dimensions to avoid costly replacements down the line.

Another issue often encountered is the quality of replacement parts. Substandard materials can compromise the integrity of the cylinder, causing leaks or failures. It’s vital to source parts from reputable suppliers who adhere to industry standards. Conducting thorough research and reading reviews can help ensure the quality of your replacements.

**Tips:** To mitigate these issues, consider implementing a regular maintenance schedule for your hydraulic systems to catch potential problems early. Additionally, keep a detailed inventory of all parts and their specifications to streamline the replacement process. Whenever possible, consult with a professional to identify the best replacement solutions tailored to your specific hydraulic needs.

Evaluating Quality and Reliability in Replacement Component Options

When it comes to hydraulic cylinder replacement parts, the quality and reliability of components can significantly affect system performance and longevity. Evaluating various alternatives requires a keen eye on the material composition and engineering standards used in manufacturing.

High-quality replacement parts are often made from durable materials that can withstand extreme pressure and environmental conditions. Buyers should seek options that meet or exceed OEM specifications, ensuring compatibility and performance.

Moreover, reliability is paramount when selecting replacement parts. This can be assessed through certifications and testing processes that the components have undergone. Quality assurance measures, such as rigorous inspection and performance testing, provide insight into the durability and efficiency of the parts. Engaging with reputable suppliers who offer warranties on their products can further safeguard your investment, offering peace of mind that you're not just choosing based on price, but on proven performance and reliability. This comprehensive evaluation will ultimately lead to better operational efficiency and reduced downtime in hydraulic systems.

Cost-Effective Strategies for Sourcing Hydraulic Cylinder Parts

When it comes to sourcing hydraulic cylinder replacement parts, cost-effectiveness is often a top priority for businesses. Exploring diverse alternatives not only helps in reducing expenses but also enhances the availability and performance of hydraulic systems. One effective strategy is to consider refurbished parts. These components are often available at a fraction of the cost of new ones and can deliver reliable performance, given they are sourced from reputable suppliers.

Another valuable approach is to forge relationships with multiple suppliers. This can provide access to exclusive deals and a wider range of products. Being open to different materials and designs can also yield significant savings. For instance, opting for aftermarket parts or alternative materials that meet the specifications can maintain the system's integrity while cutting costs.

**Tips:** Always request samples or specifications before making bulk purchases to ensure the quality meets your requirements. Additionally, consider engaging in bulk purchasing or long-term contracts with suppliers, which often leads to better pricing and supply stability. Finally, keep an eye on industry trade shows or online marketplaces, where new and innovative parts can often be found at competitive prices.

Exploring Diverse Alternatives for Hydraulic Cylinder Replacement Parts - Cost-Effective Strategies for Sourcing Hydraulic Cylinder Parts

| Alternative Source | Type of Parts | Cost Estimate ($) | Delivery Time (Days) | Quality Rating (1-5) |

|---|---|---|---|---|

| Local Manufacturer | Seals and Gaskets | 150 | 7 | 4 |

| Online Retailer | Cylinder Rods | 200 | 5 | 5 |

| Aftermarket Supplier | Complete Cylinders | 600 | 14 | 3 |

| OEM Provider | Piston Assemblies | 750 | 10 | 4 |

| Recycling Center | Cylinders | 300 | 12 | 4 |

Comparative Analysis of OEM vs. Aftermarket Replacement Solutions

When considering hydraulic cylinder replacement parts, a crucial decision involves choosing between OEM (Original Equipment Manufacturer) and aftermarket solutions. According to a report by Research and Markets, the global hydraulic cylinder market is expected to reach $16 billion by 2026, driven by increased demand for efficient and durable hydraulic systems across various industries. OEM parts are often lauded for their quality assurance, as they are manufactured to the exact specifications of the original components. However, they usually come with a higher price tag, making them less accessible for some businesses.

On the other hand, aftermarket solutions, which represented approximately 40% of the hydraulic parts market in 2022, offer a cost-effective alternative without significantly compromising quality. A study by Technavio highlights that advancements in production technologies are enabling aftermarket manufacturers to produce parts that meet or exceed OEM standards. This shift has made aftermarket components a viable option for many companies, especially those looking to optimize their maintenance costs. As businesses navigate the myriad of replacement part options, understanding the comparative benefits of OEM versus aftermarket solutions is essential for making informed decisions.

Innovative Materials and Technologies in Hydraulic Cylinder Repairs

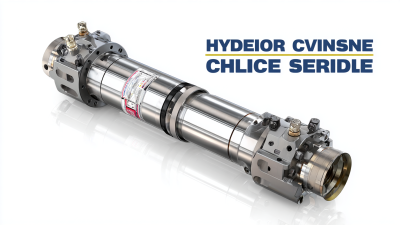

In the realm of hydraulic cylinder repairs, the integration of innovative materials and technologies is shifting the landscape. Engineers and technicians are increasingly turning to advanced composites, such as carbon fiber or reinforced plastics, which provide strength while reducing weight. These materials not only enhance performance but also extend the lifespan of hydraulic components, making them an attractive alternative to traditional metal parts.

Tips: When considering replacements, assess the specific demands of your hydraulic system. Different applications may benefit from various materials; for instance, high-temperature environments could require specialized thermal-resistant composites.

Furthermore, modern technologies such as 3D printing are revolutionizing the repair process. This method allows for rapid prototyping and production of complex components that can be customized to meet unique specifications. As a result, downtime is minimized, and costs can be significantly reduced.

Tips: Collaborate with suppliers who are well-versed in cutting-edge manufacturing processes to ensure that your replacement parts are both reliable and tailored to your needs. Emphasizing innovation in repairs not only boosts efficiency but also opens new avenues for hydraulic system enhancement.

Exploring Alternatives for Hydraulic Cylinder Replacement Parts

Related Posts

-

Understanding Industry Standards: How to Choose the Best Hydraulic Cylinder Service for Your Needs

-

Hydraulic Cylinder Rebuilders Shine at Canton Fair 2025 with Record International Attendance

-

Understanding Global Import Standards: A Guide to Sourcing Custom Made Hydraulic Cylinders

-

Innovative Strategies for Effective Hydraulic Cylinder Maintenance and Repair Solutions

-

How to Identify Top 7 Manufacturers of Hydraulic Cylinders for Global Buyers

-

Navigating the 2025 Tech Landscape: A Comprehensive Checklist for Optimal Hydraulic Cylinder Service