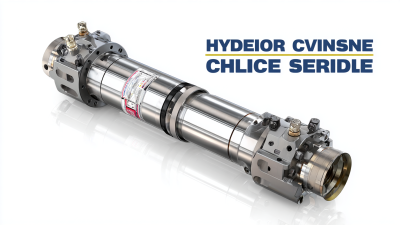

How to Extend the Lifespan of Your Hydraulic Cylinder Service

In the realm of industrial machinery, the efficiency and longevity of hydraulic systems are paramount, significantly influencing overall operational productivity. According to a report by the International Hydraulic Society, proper maintenance and service of hydraulic cylinders can enhance their lifespan by up to 30%, reducing the costs associated with unexpected downtime and repairs. Hydraulic Cylinder Service is critical not only for ensuring optimal performance but also for maximizing return on investment. With increasing demands for reliability and efficiency in various sectors, extending the lifespan of these components has become an essential focus for industry professionals.

Implementing preventative maintenance strategies and understanding the intricacies of hydraulic systems can lead to substantial improvements in both functionality and durability, ultimately ensuring a smoother and more cost-effective operational workflow.

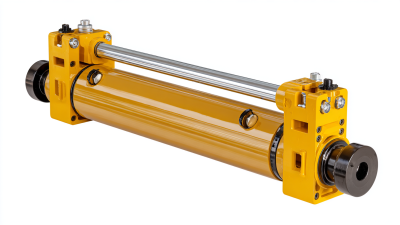

Best Practices for Regular Maintenance of Hydraulic Cylinders

Regular maintenance of hydraulic cylinders is crucial to prolong their lifespan and ensure optimal performance. According to a report from the International Hydraulic Association, proper maintenance can extend the service life of hydraulic components by up to 30%. Key best practices include routine inspections, which allow for early detection of wear and tear, and timely replacement of worn seals and components. Additionally, maintaining proper fluid levels and ensuring the use of recommended hydraulic oils can significantly reduce the risk of contamination and system failures.

Another critical aspect of hydraulic cylinder maintenance is the lubrication of moving parts. The American Society of Mechanical Engineers (ASME) emphasizes that routine lubrication prevents excessive friction, which can lead to overheating and premature failure. It is recommended to lubricate hydraulic cylinders at least once every six months, depending on the operating environment and frequency of usage. Furthermore, monitoring the hydraulic oil’s viscosity and replacing it regularly helps prevent buildup that can hinder performance and cause damage to the cylinders. By adhering to these best practices, operators can significantly enhance the efficiency and longevity of hydraulic cylinders in various applications.

Understanding the Impact of Hydraulic Fluid Quality on Cylinder Longevity

The longevity of hydraulic cylinders is significantly influenced by the

quality of hydraulic fluid

used in the system. Poor-quality or contaminated hydraulic fluid can lead to increased

wear and tear on cylinders, resulting in reduced performance and, ultimately,

premature failure. It's essential to use

high-quality hydraulic fluids

that meet the specifications required for your equipment, as this can enhance

lubrication and reduce contaminants that may cause damage.

Tips:

Regularly check and maintain fluid cleanliness and condition. Implement a routine filter

replacement schedule to ensure that impurities do not compromise the hydraulic system.

Consider using fluid additives designed to prevent oxidation and thermal degradation,

which can help maintain fluid integrity over prolonged use.

Moreover, different operating conditions can necessitate specific types of hydraulic fluids.

For example, environments with extreme temperatures

may require fluids with enhanced thermal stability. Understanding these requirements not only prolongs

the lifespan of hydraulic cylinders but also optimizes their operation efficiency.

Always consult with manufacturers to select the most appropriate hydraulic fluid for your

specific applications.

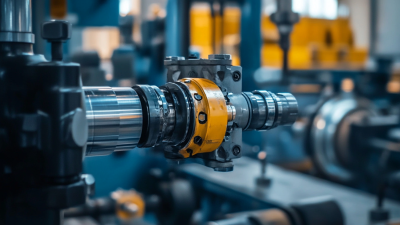

Essential Inspection Techniques to Identify Wear and Tear Early

Regular inspections are crucial for extending the lifespan of hydraulic cylinders, as they help identify wear and tear early. Utilizing advanced technologies, such as autonomous mobile robots and AI-driven systems, can significantly enhance inspection processes. These innovations can automatically detect faults and assess the condition of hydraulic cylinders, making inspections more efficient and effective. By spotting issues at an early stage, maintenance teams can proactively address problems before they escalate, thereby reducing downtime and repair costs.

Essential inspection techniques involve both visual assessments and automated solutions. For example, new laser scanning systems can monitor the condition of hydraulic components in tough environments, providing precise data on surface wear. Additionally, employing machine learning algorithms can help recognize patterns of deterioration over time, guiding maintenance efforts more strategically. By implementing these robust inspection strategies, operators can ensure the reliability and longevity of their hydraulic cylinders, ultimately leading to safer and more productive operations.

The Role of Temperature Control in Extending Hydraulic Cylinder Life

Temperature control plays a vital role in extending the lifespan of hydraulic cylinders. According to a report by the Hydraulic Institute, maintaining operating temperatures between 30°C and 60°C (86°F to 140°F) can significantly reduce wear and tear on cylinder components. High temperatures can lead to accelerated degradation of seals and oils, resulting in increased friction and eventual failure. By implementing effective cooling systems or using temperature-resistant fluids, operators can ensure that their hydraulic systems function optimally over an extended period.

Tip: Regularly monitor and maintain the cooling systems in your hydraulic machinery to prevent overheating. Consider installing temperature sensors that alert operators when critical thresholds are exceeded.

In addition to maintaining appropriate temperatures, ensuring efficient heat dissipation is crucial. Proper ventilation around hydraulic systems and strategic placement of cooling elements can help manage heat build-up. A study from the International Fluid Power Society highlighted that heat buildup can decrease oil viscosity, leading to poor lubrication and increased component wear. Therefore, optimizing heat dissipation methods not only improves performance but also prolongs equipment life.

Tip: Schedule routine inspections of hydraulic systems to identify heat retention points and address them proactively.

Implementing Predictive Maintenance Strategies to Prevent Cylinder Failure

Implementing predictive maintenance strategies is crucial for extending the lifespan of hydraulic cylinders. According to a report from the International Journal of Industrial Engineering, predictive maintenance can reduce maintenance costs by up to 30% and improve equipment reliability by as much as 25%. By utilizing data analytics and real-time monitoring, operators can foresee potential failures before they occur, allowing for timely interventions and minimizing downtime.

To effectively implement predictive maintenance, regularly analyze operating conditions and wear patterns. Tips for monitoring include using vibration analysis tools and pressure sensors, which can provide early warnings of mechanical issues. It's also essential to maintain accurate records of cylinder performance, as this data can reveal trends that indicate when maintenance should be performed, thereby preventing unexpected failures.

Another critical tip is scheduling routine inspections and incorporating advanced diagnostic technologies, such as ultrasound and thermography. A study from the Society of Manufacturing Engineers found that adopting such technologies can enhance detection rates of impending failures by 40%. By proactively addressing issues, businesses can ensure the longevity and efficiency of their hydraulic cylinders, ultimately contributing to the overall productivity of their operations.

Related Posts

-

The Complete Blueprint to Mastering Hydraulic Cylinder Service

-

Understanding Industry Standards: How to Choose the Best Hydraulic Cylinder Service for Your Needs

-

Navigating the 2025 Tech Landscape: A Comprehensive Checklist for Optimal Hydraulic Cylinder Service

-

Discover the World-Class Quality of China's Best Hydraulic Cylinders for Global Buyers

-

The Future of Hydraulic Piston Repair Innovations Shaping the Industry Beyond 2025

-

Innovative Strategies for Effective Hydraulic Cylinder Maintenance and Repair Solutions