Top Strategies for Optimizing Your Best Hydraulic Cylinder System Performance

In today’s highly competitive industrial landscape, optimizing the performance of your Hydraulic Cylinder System is crucial for enhancing productivity and reducing operational costs. According to a recent report by the International Society for Automation, hydraulic systems account for over 50% of the energy consumption in many industrial processes, emphasizing the need for efficiency improvements. Furthermore, the market for hydraulic cylinders is projected to reach $20 billion by 2026, fueled by rapid advancements in technology and increased demand in sectors such as construction and manufacturing. Implementing top strategies to fine-tune hydraulic cylinder systems can lead to significant improvements in reliability and performance, ultimately driving better economic outcomes for businesses. This tutorial will explore key methodologies and best practices designed to help organizations make the most of their hydraulic systems.

Understanding Hydraulic Cylinder Alternatives for Enhanced Performance

When it comes to enhancing the performance of hydraulic cylinder systems, understanding alternatives plays a crucial role. Many industries are now exploring advanced alternatives to traditional hydraulic cylinders, such as electric actuators and hybrid systems. According to a report by Transparency Market Research, the global electric actuator market is expected to grow at a CAGR of 5.8% from 2021 to 2028. This growth is driven by the increasing demand for energy-efficient and precise control systems across various applications, from manufacturing to automotive.

One effective strategy for optimizing hydraulic systems is to incorporate smart monitoring technologies. By implementing IoT sensors, operators can gather real-time data on cylinder performance, which helps in predictive maintenance and avoids costly downtime. For instance, a study from McKinsey suggests that predictive maintenance can reduce maintenance costs by up to 25%, significantly enhancing system reliability and efficiency.

Tips: Consider upgrading to smart actuators that not only improve efficiency but also reduce maintenance efforts. Additionally, evaluate the compatibility of electric systems with existing hydraulic setups to ensure a seamless transition. Lastly, regularly assess the market for emerging hydraulic alternatives, as innovations can lead to substantial operational improvements.

Evaluating the Benefits of Different Hydraulic Cylinder Materials

When it comes to optimizing the performance of hydraulic cylinder systems, evaluating the materials used in the cylinders is crucial. Different materials offer unique benefits that can significantly influence the efficiency and longevity of the hydraulic systems. For instance, aluminum cylinders are lightweight and resistant to corrosion, making them suitable for applications where weight reduction is essential. However, they may not withstand as much pressure as steel cylinders.

On the other hand, steel is renowned for its strength and durability. Cylinders made from high-strength steel can handle extreme pressures and harsh conditions, making them ideal for heavy-duty applications. Additionally, advancements in composite materials provide an exciting alternative; these materials can combine the best properties of metals and plastics—offering both lightweight characteristics and improved resistance to wear and corrosion. Selecting the right material based on the specific application requirements can lead to improved performance, reduced maintenance costs, and a longer lifespan for hydraulic cylinder systems.

Top Strategies for Optimizing Hydraulic Cylinder Performance

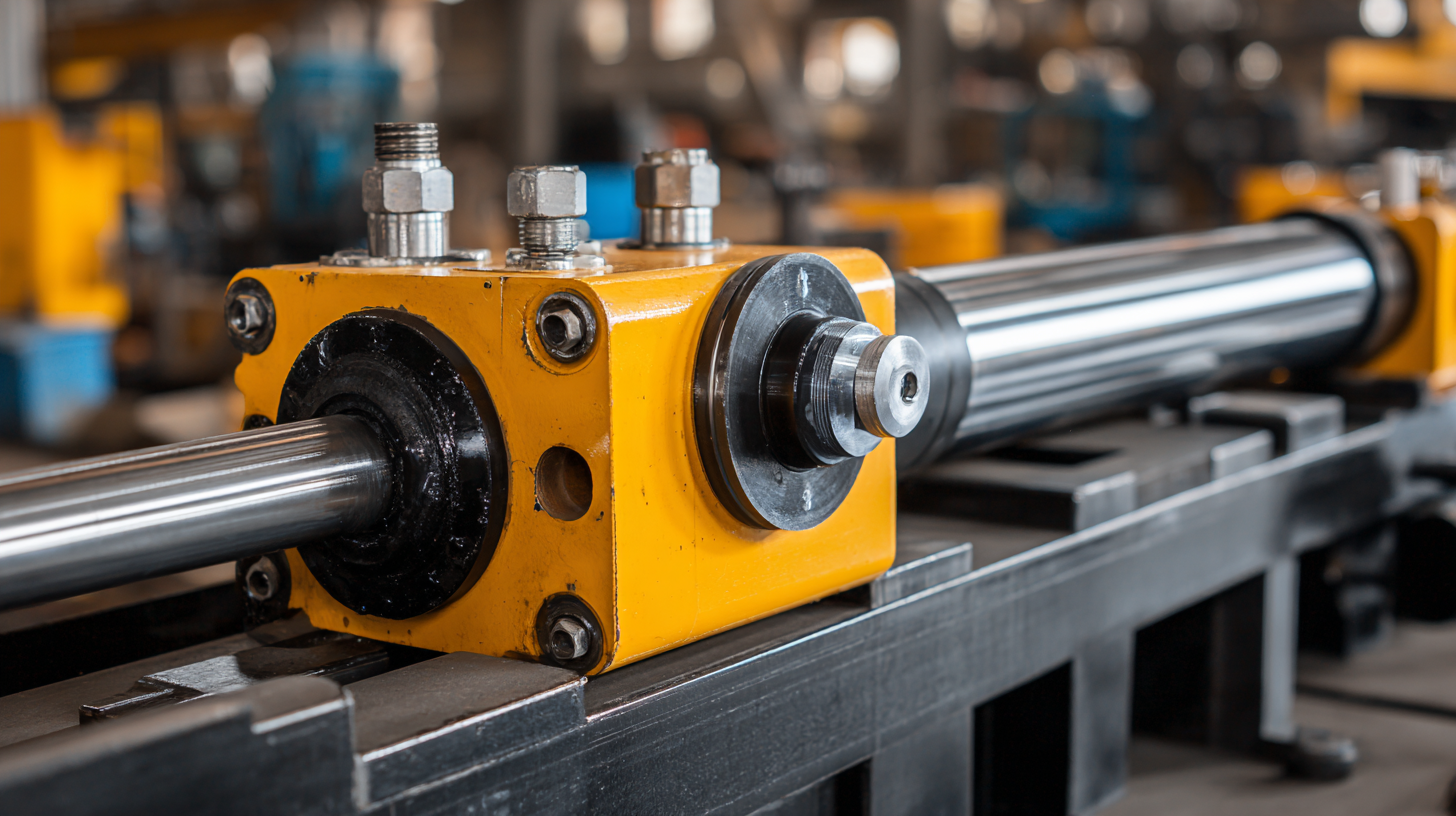

Comparative Analysis of Single-Acting vs. Double-Acting Cylinders

When evaluating hydraulic systems, understanding the distinction between single-acting and double-acting cylinders is crucial for optimizing performance. Single-acting cylinders operate in one direction, using hydraulic pressure to extend while relying on gravity or a spring to retract. This simplicity can result in lower initial costs and ease of installation, making them ideal for applications where force is needed in one direction, such as in clamping or lifts.

When evaluating hydraulic systems, understanding the distinction between single-acting and double-acting cylinders is crucial for optimizing performance. Single-acting cylinders operate in one direction, using hydraulic pressure to extend while relying on gravity or a spring to retract. This simplicity can result in lower initial costs and ease of installation, making them ideal for applications where force is needed in one direction, such as in clamping or lifts.

In contrast, double-acting cylinders use hydraulic pressure for both extension and retraction, offering greater versatility and control. This design makes them suitable for tasks that require consistent force in both directions, improving efficiency and overall cycle times. While the complexity of double-acting systems may lead to higher maintenance requirements, their ability to handle demanding operations in factories, construction sites, and heavy machinery can make them a more advantageous choice in the long run. Understanding the specific needs of your application is key to selecting the appropriate type of cylinder for optimal hydraulic system performance.

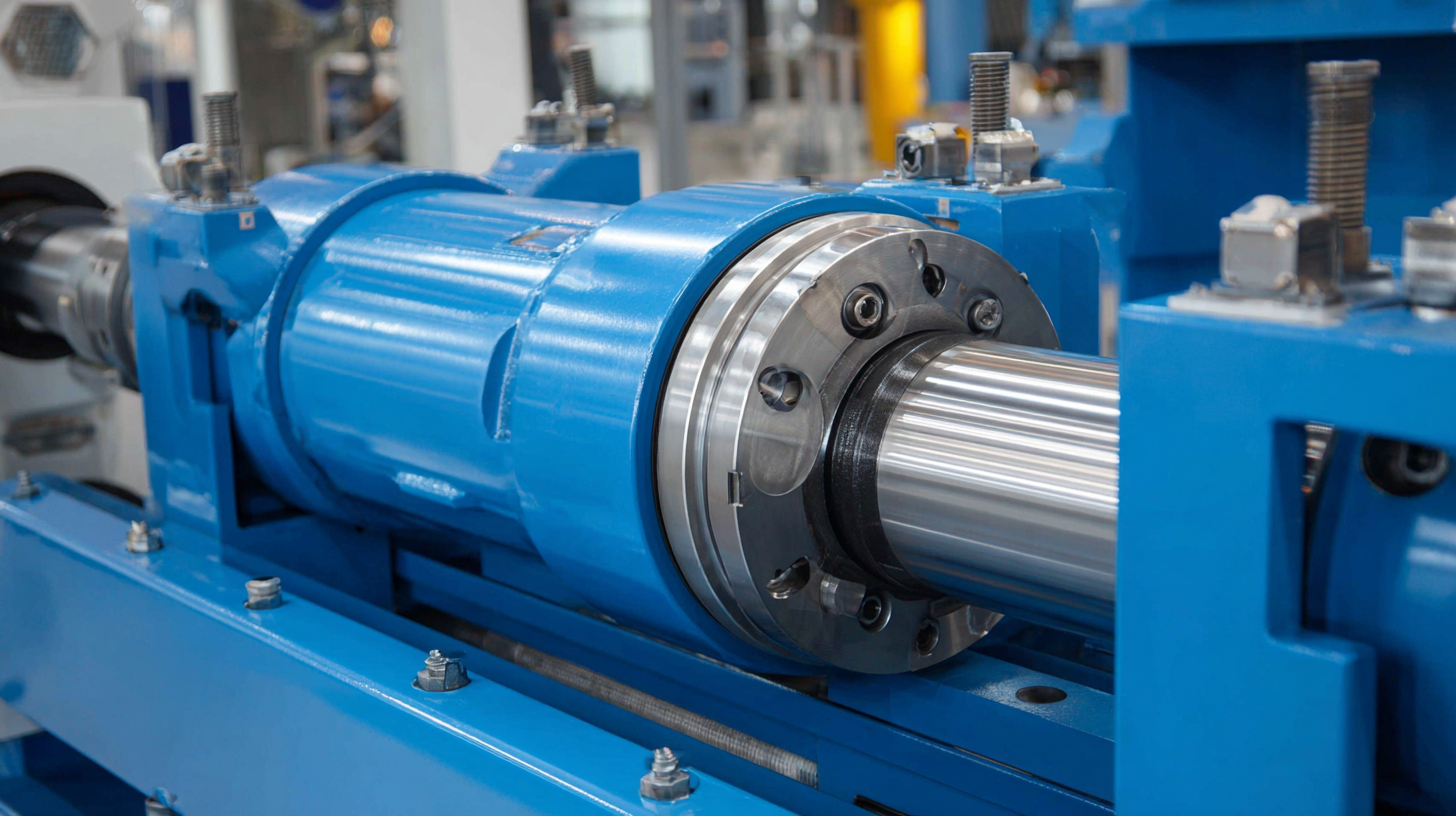

Innovative Design Features in Modern Hydraulic Cylinder Systems

Modern hydraulic cylinder systems have evolved significantly with innovative design features that not only enhance their efficiency but also extend their operational lifespan. One of the most notable advancements is the integration of smart sensors embedded within the cylinders. These sensors provide real-time data on pressure, temperature, and fluid levels, allowing operators to monitor performance closely and make informed adjustments to optimize the system's functionality. Such capabilities minimize the risk of failure and ensure that the hydraulic system operates within its optimal parameters.

Another key feature in contemporary hydraulic cylinders is the use of advanced materials and coatings. High-strength alloys and corrosion-resistant surfaces increase durability, reducing the maintenance required and the potential for costly repairs. Additionally, the development of low-friction seals and improved hydraulic fluid formulations enhances the overall efficiency of the system, resulting in reduced energy consumption and improved response times. These innovations not only contribute to better performance but also support sustainable practices by lowering operational costs and environmental impact.

Maintenance Practices for Prolonging the Life of Alternative Hydraulic Solutions

Effective maintenance practices are crucial for prolonging the life of alternative hydraulic solutions, which can greatly impact system performance and reliability. According to a study by the International Fluid Power Society (IFPS), regular maintenance can extend the lifespan of hydraulic cylinders by up to 50%. This not only reduces downtime but also minimizes replacement costs, making maintenance an essential aspect of hydraulic system management.

Effective maintenance practices are crucial for prolonging the life of alternative hydraulic solutions, which can greatly impact system performance and reliability. According to a study by the International Fluid Power Society (IFPS), regular maintenance can extend the lifespan of hydraulic cylinders by up to 50%. This not only reduces downtime but also minimizes replacement costs, making maintenance an essential aspect of hydraulic system management.

One key practice is the routine inspection and replacement of hydraulic fluids. The National Fluid Power Association (NFPA) reports that contamination is the leading cause of hydraulic failure, accounting for nearly 70% of the issues faced in hydraulic systems. By adhering to recommended fluid change intervals and using certified filtration systems, facility managers can significantly mitigate the risk of fluid-related failures.

Furthermore, incorporating condition monitoring technologies is becoming increasingly popular. The use of predictive maintenance tools—such as vibration analysis and thermal imaging—can help identify potential failures before they escalate. A report from MarketsandMarkets estimates that predictive maintenance technologies can reduce maintenance costs by 20-25% while improving uptime and system efficiency. By integrating these advanced practices, businesses can ensure their hydraulic systems run optimally, thus enhancing productivity and reducing operational costs.